Most of all, the safety and quality of food are of utmost importance. We support food & beverage testing heroes by: Partnering with leading global scientists to ensure access to the gold-standard food and beverage products of today and tomorrow. Working alongside leading experts enables us to develop innovative solutions that meet the unique

Figure 11. Membrane filters come in a variety of sizes, depending on the volume of solution being filtered. (a) Larger volumes are filtered in units like these. The solution is drawn through the filter by connecting the unit to a vacuum. (b) Smaller volumes are often filtered using syringe filters, which are units that fit on the end of a syringe.

Critical in new formulation development and quality control testing during manufacturing, dissolution testing is used to measure active pharmaceutical ingredient (API) release over time. Dissolution testing is required for all solid, oral formulations and utilizes filtration to stop the dissolution process. Depending on the membrane type and

A machine vision system inspects Acrodisc PSF syringe filters throughout the production process for cosmetic defects. Operators and technicians verify the pad printing on the Acrodisc syringe filters. Lettering quality, accuracy, and proper color-coding stamped on each device are inspected. Package labeling is examined for

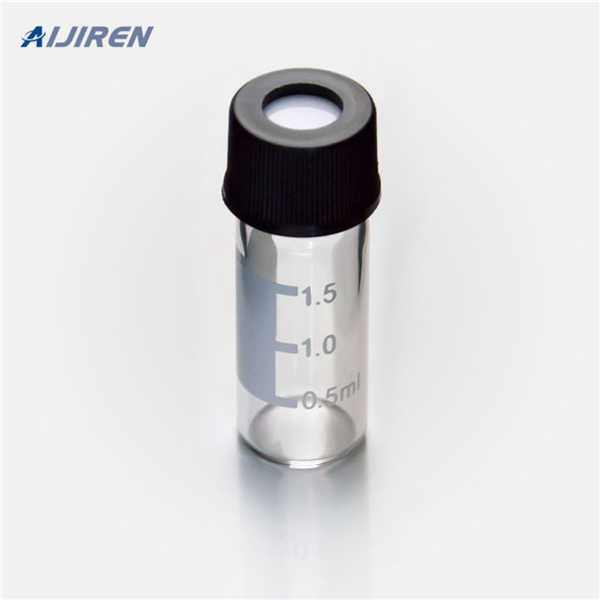

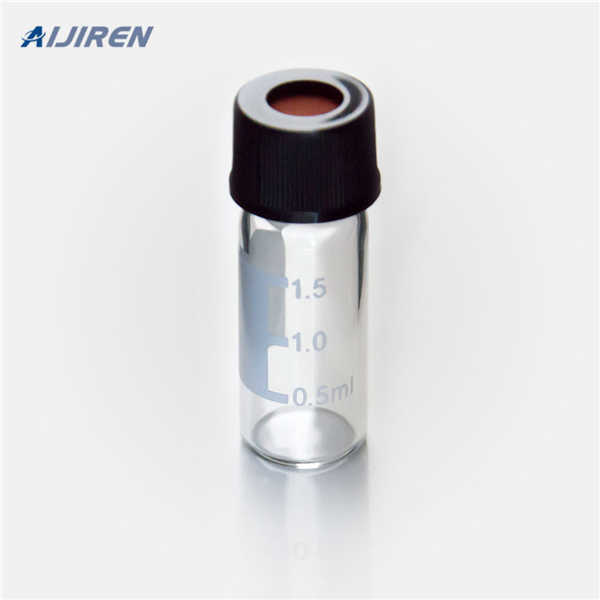

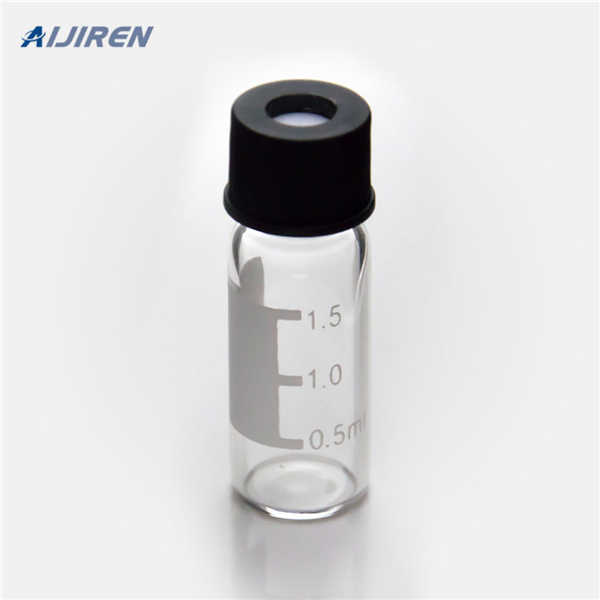

A syringe filter (or wheel filter) is a single-use, membrane-based device used for the removal of particulate impurities from small (≤ 100 mL) liquid samples ( Figure 1 ).

Volumetric sample recovery from various syringe filters was determined by filtration of a fixed volume of sample through the syringe filter and measuring the volume of liquid collected in a vial. This provided information about volume retained by a syringe filter and its impact on analyte binding.

.jpg)

¥ÿŸ `ž{¸ çb õŸžìý ×—Ó»èËþåõUßÅô®úúúúôLÅ&‡á÷/ t( ôïV[[t’É¿ ¿uÐY ž¼ ݵÿ[Ý’/ AK íðÖ‚ •¶æy Q»- à 3 ,PJ[’&Øn ´T‚ ò rs¶µ¹§;Êòéƒ 7?

Aug 30, 2023 · 1. Introduction: Syringe filters are vital components of laboratory filtration systems, designed to remove particles and contaminants from liquids and gases. Their compact design, versatility, and ease of use make them a preferred choice for sample preparation in research, quality control, and various analytical applications.

Millex. Syringe Filters. Setting the standard in small-volume filtration (1-200 mL), the unsurpassed consistency of Millex ® syringe filters in sample preparation has led to the development of many methods specifying their use. Featuring reduced sample loss due to minimal hold-up volumes, Millex ® syringe filters are ideal for use in a

5 |What to control?, BWP Workshop on Setting Specifications | Thomas Stangler, September 9th, 2011. Assessing quality attribute criticality Start with list of all possible quality attributes – Consider mode of action and molecule type Risk-based approach to identify CQAs – Links quality attributes to safety and efficacy

Syringe Filters . for Analytical Sample Preparation; Including HPLC and Dissolution Testing. Analytical Technical Guide for: •Choosing a Syringe Filter •Extending HPLC Column Life •Extractables •Drug Binding. For more information: WEB: FLTR.com.au PHONE: (+61) 1300 62 4020 EMAIL: info@FLTR.com.au SKYPE: Purple.Engineering

Millex® Syringe filters set the standard for reliable small volume filtration (1 mL to 200 mL). Available in 4, 13, 25, 33, and 50 mm diameters. Minimal hold-up volume for less sample loss o f small volumes and are ideal for solutions such as antibiotics and tissue culture additives. Their unsurpassed quality and consistency of results has led

Phenex syringe filters are designed for efficient and rapid filtration of almost any solution prior to analysis, and are optimized for superior flow rates and high-throughput. Phenex offers a wide variety of membranes ideal for any application. The housing attaches to any standard luer lock syringe, so the sample can easily be pushed through

Syringe Filters. Syringe filters are single-use, membrane-based devices used for the removal of particulate impurities from liquid and gas samples prior to analysis by methods such as HPLC, ion chromatography, gas chromatography, ICP, and dissolution testing. Proper filtration of samples improves the quality and consistency of analytical

Oct 17, 2022 · The medical device and life sciences industry must meet stringent regulations for quality and product consistency, making process control a critical issue. All materials and manufacturing processes – including machining, assembly and packaging – must be documented for complete traceability and process validation.