Thermo Scientific Nalgene sterile syringe filters are ideal for sterilizing (0.2 micron) or clarifying biological solutions, such as cell culture and microbial media, reagents and additives, proteinaceous solutions, and buffers. PES (polyethersulfone) – Lowest protein binding and. Related Products: 2 Micron Filter.

applications in life science, pharmaceutical, environmental, biotechnology, food & beverage, and agricultural testing laboratories. Products MS® sterile syringe are made filters from PES membrane filters with polypropylene (PP) housing. PES filters feature high flow rates and low protein adsorption and

Pall Lab offers Scale-Up capsules that feature the same performance and materials as Pall’s GMP Pharmaceutical grade capsules and filters which can help streamline and quicken scale-up or scale out operations. Acrodisc sterile syringe filters are ideal for small volume aseptic handling and sterile filtration of up to 150 mL solutions.

Sterile filtration, clarification, and particle removal. Minisart ® NML Syringe Filters provide the optimal method for clarification and sterilization of liquids, robustly removing bacteria and particles, without any impact on product quality or loss of target molecule. Superior filter areas up to 6.2 cm 2. 0.1µm to 5µm pore sizes.

Sterile Filtration. Available in 0.1 and 0.2 µm pore sizes, the polyethersulfone membrane provides sterilization of buffers, culture media, additives, and pharmaceutical filtration. If mycoplasma contamination is a concern, the 0.1 µm PES membrane provides assurance that critical samples will not be contaminated. Healthcare

Higher concentration of PEG results in larger pore size of the membrane filter. These filters have 66 to 78 % porosity. These filters can be sterilized by autoclaving for microbiological analysis. Generally, filters having pore sizes of 0.22µ and 0.45µ are used in pharmaceutical industries.

Automated Filter Integrity Testing (AFT): an instrument that performs the typical integrity tests used in pharmaceutical manufacturing (e.g., bubble point, diffusive flow, pressure hold, and water intrusion) Bacterial retention: validation that confirms the filter membrane’s ability to produce a sterile effluent when exposed to a

Pharmaceutical Tubing. SCHOTT’s extensive product line of high-quality Type I borosilicate glass, as well as Type III soda-lime glass tubing, has been designed to preserve active pharmaceutical ingredients to ensure their effectiveness. FIOLAX® is the premium standard for the production of syringes, cartridges, vials and ampoules.

Categories of Pharmaceutical Packaging Materials. Primary packaging system is the material that first envelops the product and holds it i.e., those package components and subcomponents that actually come in contact with the product, or those that may have a direct effect on the product shelf life e.g., ampoules and vials, prefilled syringes, IV containers, etc.

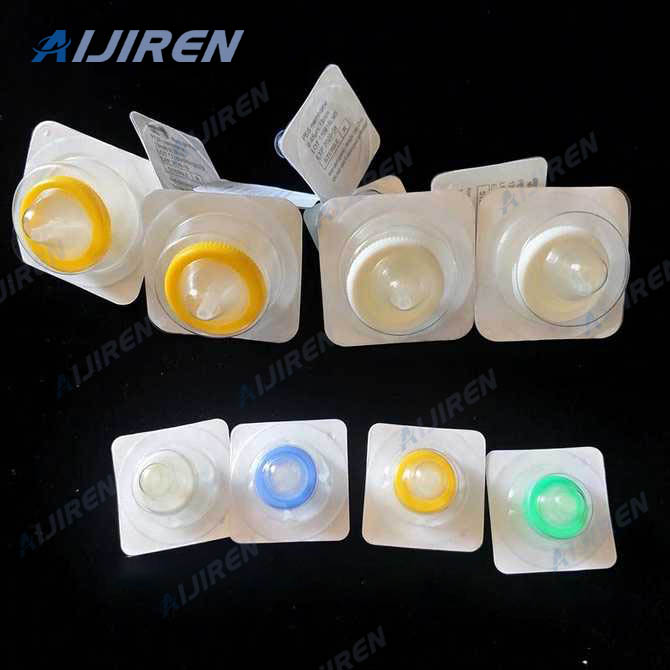

Based on product, sterile filtration market is segmented into cartridge filters, capsule filters, membranes, syringe filters, bottle-top & table-top filtration systems, and accessories. On the basis of membrane pore size, sterile filtration market is segmented into 0.2–0.22 µm, 0.45 µm, and 0.1 µm.

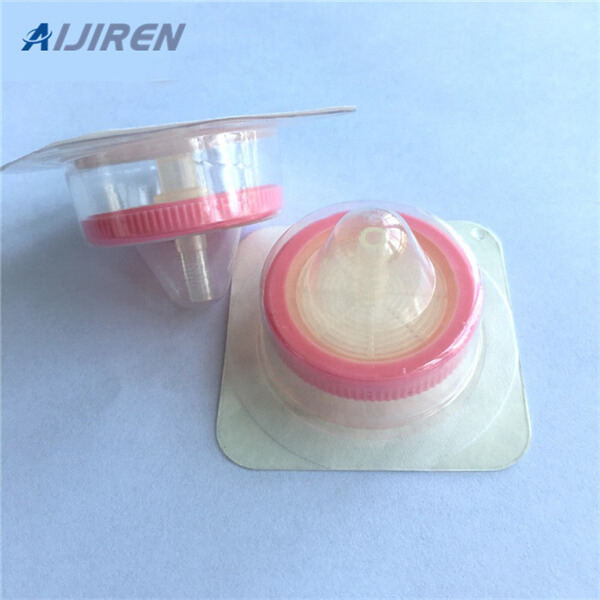

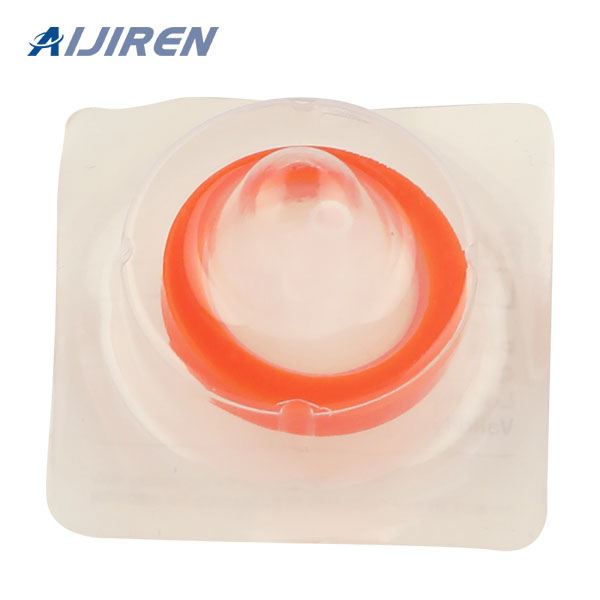

Feb 17, 2020 · Note: The individually packed sterile syringe filter can be held in the original package to minimize contamination while attaching the syringe. Step 3: Secure the Syringe Filter. Secure the syringe filter using a clockwise motion with luer-lock syringe. DO NOT overtighten. Step 4: Filter the Solution. Hold the assembled syringe and filter it upright.

The product line includes pore sizes ranging from 0.1 μm to 5.0 μm to ensure a comprehensive selection of syringe filters are available. Syringe filters are sterilized by gamma irradiation, preventing the contamination risk that can result from ethylene oxide sterilization. They are individually blister packed to ensure sterility during storage and handling. Replacing a syringe filter midway through the process may lead to contamination, spills, and workflow disruption.

Apr 16, 2020 · The highest ca. 24% and 31% loss of TPC and TFC, respectively, were observed after the filtration process using a sterile syringe filter (Millipore PES 0.22 µm).

Filter materials can also break off or come loose during filtration and appear in the filtrate. Depth filters are rigid enough to filter a solution being pulled into a syringe. They can also be used to filter a solution being pushed out of a syringe. But the same filter cannot be used to draw up and then expel a solution.

Filter validation is a critical part of various pharmaceutical QC tests, and various filter parameters need to be taken into consideration during method validation. Since accurate analyte quantitation is required in these QC tests, analyte binding is an important factor to consider during filter validation. Membrane and analyte physico-chemical